Technical Details. Tactile Guidance System for the Visually Impaired.

Stainless steel is light. Stainless steel is sound. Stainless steel creates contrasts.

The SPIN® Safe stainless steel guidance system for the blind consists of floor indicators for information, orientation, guidance and warning for blind and visually impaired people. Thanks to its high tactile, visual and acoustic contrast, SPIN® Safe stands out clearly from the neighbouring floor covering.

When it comes to public tenders, you can play it safe with Hoba Steel: with our SPIN® products and tender texts, architects and planners work in accordance with tenders and specifications based on DIN 32984 and DIN 18040.

Our stainless steel guidance system for the blind fits in perfectly with the design of many public spaces and traffic routes, as escalators, lifts and railings are preferably made of stainless steel. The flexible design options of SPIN® Safe stainless steel products give the architecture scope for numerous product combinations. Our SPIN® Safe range, divided into individual indicators and tile systems, includes guidelines and attention fields, tactile overview plans, handrail signs and step angles.

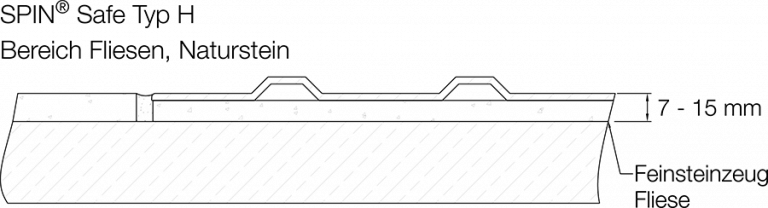

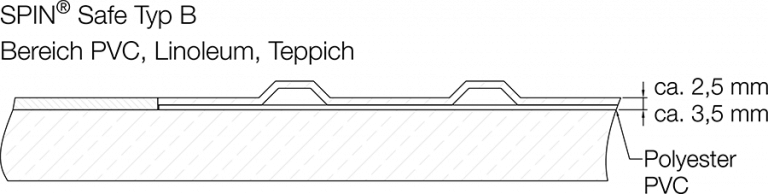

SPIN® Safe can therefore be laid in accordance with DIN 32984 for both new buildings and retrofits. The SPIN® Safe conductive tile – with the lowest possible installation height of 2.1 mm – is used for retrofitting on existing hard coverings such as natural stone, tiles and coatings. Hoba Steel offers any suitable installation height for combinations with PVC, linoleum, carpet, wood, tiles or concrete. The flexible design of the underside, which can be adapted to any neighbouring floor covering, provides maximum flexibility for the planner.

Our SPIN® products are certified for slip resistance and fire classification. It goes without saying that we will provide you with the manufacturers’ cleaning recommendations for stainless steel surfaces.

We will provide you with comprehensive advice – contact us using the contact form or give us a call.

Overview of Standards.

The top side of the SPIN® Safe guidance system for the blind is made of stainless steel 1.4301. The underside varies depending on the type (see also formats).

The slip resistance of tile systems with SPIN® Plan is certified as R9. The fire behaviour of the Plan variant is classified as B1. The slip resistance of SPIN® Cross is certified as R11 and therefore also fulfils higher standards for areas with higher wetness.

The anti-slip properties of the individual indicators cannot be conclusively determined due to the surrounding surface. We would be happy to send you certificates for the individual raw materials or samples of our products.

Overview of Surfaces.

Our guiding and raised tiles are manufactured in the SPIN® Plan surface. The contrast strips, individual indicators and steps can be manufactured in different surfaces. Special solutions such as individual indicators made of bronze or brass are also possible. Please do not hesitate to contact us!

Our Formats.

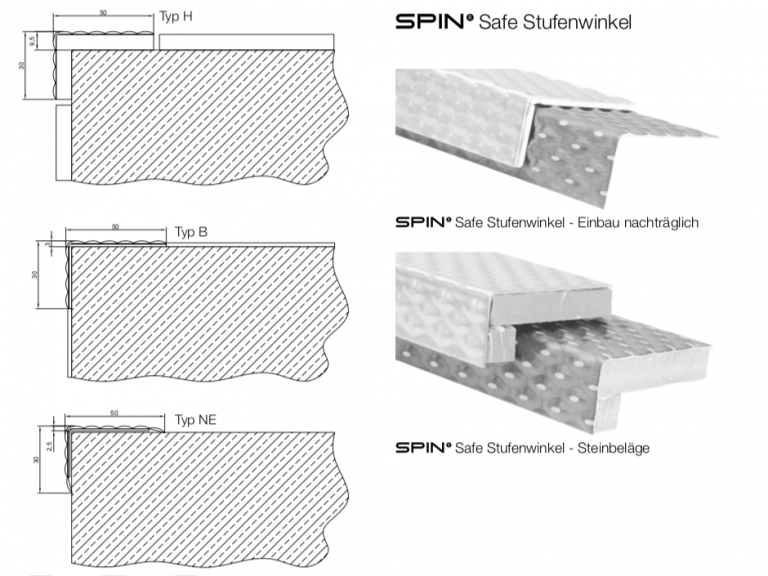

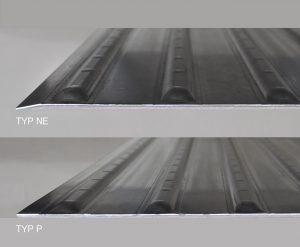

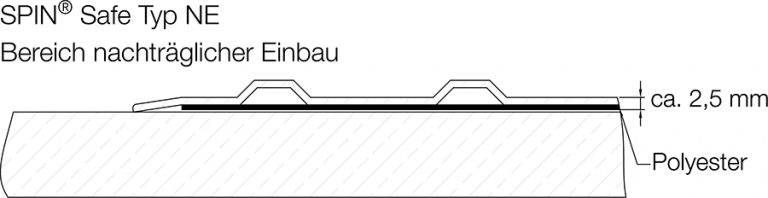

Type H has a porcelain stoneware backing with a total thickness of 10.5 mm. Type B is based on a plastic underside with a total thickness of 5 mm. Types P and NE have a polyester underside. With a total thickness of 2.1 mm, both types are particularly suitable for flat floor coverings (linoleum, PVC, carpets, etc.). Type P differs from type NE with its straight edges and rounded edges. Customised overall thicknesses are possible for all types in consultation with the Hoba Steel team.

Type H - Underside Porcelain Stoneware

SPIN® SAFE attention tiles with dimpled structure

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 298x298 | 10,5 | ||

| 398x398 | 10,5 | ||

| 450x450 | 10,5 | ||

| 550x550 | 10,5 |

SPIN® SAFE guide tile with 7 ribs

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 598x298 | 10,5 | ||

| 598x398 | 10,5 |

SPIN® SAFE guide tile with 3 ribs

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 598x122 | 10,5 | ||

| 598x222 | 10,5 |

Type B - Underside Synthetic

SPIN® SAFE attention tiles with dimpled structure

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 298x298 | 5 | ||

| 398x398 | 5 | ||

| 450x450 | 5 | ||

| 550x550 | 5 |

SPIN® SAFE guide tile with 7 ribs

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 598x298 | 5 | ||

| 598x398 | 5 |

SPIN® SAFE Guiding tile with 3 ribs

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 598x122 | 5 | ||

| 598x222 | 5 |

Type P and Type NE - Underside Fleece

SPIN® SAFE attention tiles with dimpled structure

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 298x298 | 2,5 | ||

| 398x398 | 2,5 | ||

| 450x450 | 2,5 | ||

| 550x550 | 2,5 |

SPIN® SAFE Guiding tile with 7 ribs

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 598x298 | 2,5 | ||

| 598x398 | 2,5 |

SPIN® SAFE guide tile with 3 ribs

| Tiles / mm | Thickness / mm | Plan | With Contrasting Stripes OVAL ANTHRAZITE (2x5cm) |

|---|---|---|---|

| 598x122 | 2,5 | ||

| 598x222 | 2,5 |

Edge Formation Type P & Type NE

Type P has straight cut edges. This type is suitable for laying in floors (see also the graphics for type H or type B under W under „Installation“).

Type NE has flattened edges and is suitable for subsequent installation for gluing onto existing coverings.

Installation.

All surfaces must be checked for load-bearing capacity and strength before covering with the tactile guidance system. Separating agents and dust must be removed from the surface beforehand without leaving any residue.

The information in the adhesive manufacturer’s technical data sheets must always be observed.

Type H - Underside Porcelain Stoneware

Step 1: Clean the floor

Step 2: Priming

Cement screed: Clean

Calcium sulphate screed: Prime with ARDEX P51 at a mixing ratio of 1:3 with water

Mastic asphalt screed, smooth floors and old tiles: Prime with ARDEX P82 Primer or Ardex P4 Ready

Step 3: Laying

| Recommended Material | |

|---|---|

| Floor laying: Type H | ARDEX X78 |

| Jointing Type W und Type H | ARDEX G6 Flex 1-6 |

Type B - Underside Synthetic

Step 1: Clean the floor

Step 2: Priming

- Calcium sulphate screed, cement screed: Prime with ARDEX P51 at a mixing ratio of 1:3 with water

- Mastic asphalt screed, smooth floors and old tiles: Prime with ARDEX P82 synthetic resin primer or Ardex P4 Ready

Step 3: Levelling the flow filler

We recommend ARDEX K15 DR or ARDEX K39 as levelling compound.

Step 4: Sanding the levelling compound

We recommend sanding with a parquet sander, for example.

Step 5: Laying

We recommend ARDEX Premium AF 495 or SPIN® epoxy adhesive for installation.

Type P & NE - Underside Fleece

Step 1: Clean the floor

Step 2: Laying

We recommend ARDEX Premium AF 495 or SPIN® epoxy adhesive for installation.

| Recommended Material | |

|---|---|

| FLOOR-Installation: Type W | ARDEX S28 |

| FLOOR-Installation: Type H | ARDEX X78 |

Single Dimples and Ribs

Step 1: Clean the floor, including degreasing

Step 2: Gluing on the indicators

With the help of a template (German or French spacing), the indicators are glued on one after the other. To do this, remove the protective film on the underside, place the indicator and then press firmly to activate the adhesive force. The floor can be walked on again after 72 hours.

For floors subject to particularly high levels of moisture and in areas where cleaning machines are used, e.g. in supermarkets or entrance areas, we recommend fixing the indicators with another special adhesive.

Stair Angle.